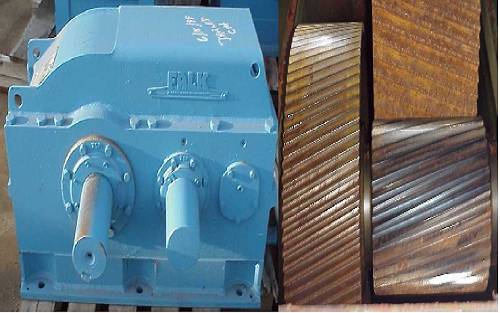

Selecting the right Falk gearbox for an application is as much an art as it is a science. Choosing the wrong Falk gear reducer can affect everything from machinery performance to facility output to compliance with federal regulations. Aside from compatibility factors such as speed, horsepower, torque and load-bearing capacity, there are many other considerations engineers should keep in mind when shopping for surplus gear reducers, including:

Selecting the right Falk gearbox for an application is as much an art as it is a science. Choosing the wrong Falk gear reducer can affect everything from machinery performance to facility output to compliance with federal regulations. Aside from compatibility factors such as speed, horsepower, torque and load-bearing capacity, there are many other considerations engineers should keep in mind when shopping for surplus gear reducers, including:

Space requirements. Within an industrial facility, space is often in short supply. That means surplus gear reducers that can efficiently slash speed without taking up a lot of real estate are a godsend. A worm drive, for example, is an extremely space-efficient type of Falk gearbox, as it is both compact and adept at quickly converting speed into torque.

Noise restrictions. Noise is also a critical deciding factor when selecting a Falk gear reducer. Industrial facilities are subject to OSHA regulations on how much noise workers can be regularly exposed to. In addition to external noise control measures, such as sound barriers and damping devices, engineers can help reduce overall noise by selecting a Falk gear reducer with a higher contact ratio between matching gears. For example, helical gears are less noisy than spur gears because they provide a greater contact area between gears. Similarly, spiral bevel gears don’t make as much noise as straight bevel gears.

Gear drive configuration. A replacement Falk gearbox must be able to soundly connect with surrounding components, which may be arranged in any number of configurations. Some systems involve axes that are parallel to each other, while others meet at a right angle. Some structures don’t fall into either category. Different surplus gear reducers are best-suited for different configurations; engineers must take this information into consideration.

There are many other factors that affect which type of Falk gear reducer is best for a specific task – these are just a few. The key is to do careful research and make a well-informed decision. It’s also helpful to choose an experienced Falk supplier who can help ensure you get the right device.

Posted under Products/Services on Monday, February 6th, 2012