Torsional flexibility, or the ability to handle shock or vibratory loads, is an important consideration when choosing a coupling. In addition to accommodating shaft misalignment, a well-designed coupling should be able to absorb the energy of impact and spread it out over time. This is one of the reasons the Falk F coupling remains in demand, despite the fact that it’s now obsolete (replaced by the newer T coupling).

Torsional flexibility, or the ability to handle shock or vibratory loads, is an important consideration when choosing a coupling. In addition to accommodating shaft misalignment, a well-designed coupling should be able to absorb the energy of impact and spread it out over time. This is one of the reasons the Falk F coupling remains in demand, despite the fact that it’s now obsolete (replaced by the newer T coupling).

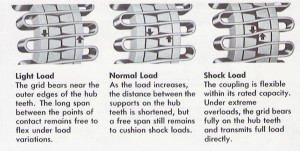

Because of its flexible grid design, the F coupling is able to dampen vibrations and reduce peak or shock loads by as much as 30 percent – making it a true shock absorber for rotary motion that can help preserve the life of your machinery. Here’s a look at how the F coupling handles various loads:

Light load: When handling lighter loads, the F coupling’s Steelflex grid bears near the outside edges of the hub teeth, creating a long span between contact points to allow for flexibility under load variations.

Normal load: An increase in load causes the distance between points of contact to shorten, supporting the heavier load while still providing some flexibility to cushion shock loads.

Shock load: Within its rated capacity, the F coupling remains flexible. Extreme overloads cause the grid to bear fully on the hub teeth, directly transmitting the full load.

Posted under Products/Services on Friday, May 25th, 2012