Time to shift gears—it’s a phrase we still commonly use in conversation. But how many people understand where it comes from?

The actual act of shifting gears is quickly becoming obsolete as demand for automatic transmissions increases. Many manufacturers are phasing out engines that require the operator to manually shift gears. Twenty-five years ago, one in four vehicles sold in the United States had a stick shift. By 2012, manuals were down to just 7 percent.

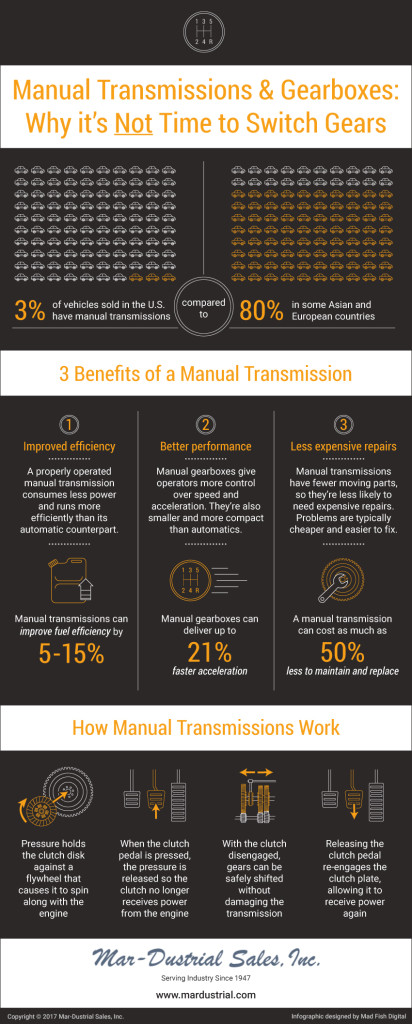

Today, fewer than 3 percent of vehicles sold nationally have manual transmissions—compared to 80 percent in some Asian and European countries. Analysts predict the stick shift will disappear entirely over the next couple of decades.

It’s a phenomenon that has prompted U.S. News & World Report to ask, “Why are manuals disappearing?” and Car and Driver magazine to start a campaign to #SavetheManuals.

It’s not just happening on the roads, either. Today’s heavy industrial machinery increasingly features automatic gear shifting, and that’s not necessarily a good thing. Although automatic transmissions may seem simpler to operate on the surface, they’re much more complex and difficult to repair than manuals.

How manuals and automatics differ

The stick shift is the oldest and simplest type of transmission. A manual gearbox uses a friction clutch to connect the engine’s rotational energy to the transmission’s input shaft. Using a foot pedal to disengage the clutch from the engine, the operator is able to safely able to shift gears as needed. Until the 1950s, most vehicles in the United States featured manual transmissions.

Automatics came along in the 1930s, but they didn’t become widespread until after World War II. This type of gearbox transmits rotational energy from the engine using a highly complex torque converter, while the vehicle’s computer controls the gear shifting through a planetary gear set and a series of clutches and brakes. Despite their complex design, automatics quickly caught on among American drivers and have grown in ubiquity ever since.

“Though the behind-the-scenes action is quite complicated, all the driver has to do is select from the familiar P-R-N-D-L choices on the gear selector,” says The Cheat Sheet. “The trade-off for the driving simplicity is mechanical complexity, which makes the automatic more prone to failure and pricier to fix.”

Benefits of a manual transmission

Despite the burgeoning popularity of the automatic transmission, Oregon gearbox experts recommend giving manual gear shifting another chance. Although they require more training to operate, manual transmissions can ultimately save industrial operations thousands of dollars in maintenance and repair costs over the lifetime of the machinery.

The advantages of a manual transmission include:

Improved efficiency. Since they’re more streamlined than automatic transmissions, manuals weigh less and take up less space. They also run more efficiently, consuming less fuel or power than their automatic counterparts. Consumer Reports found that when properly operated, manual transmissions can offer 5 to 15 percent better fuel efficiency.

Enhanced performance. Manual gear shifting allows greater control over speed and acceleration, allowing the operator to optimize the engine’s performance. In vehicles, a manual gearbox can deliver up to 21 percent faster acceleration.

Cheaper repairs. Since manual transmissions comprise fewer moving parts than automatics, they’re more reliable and less prone to catastrophic failures. When problems do occur, they’re often cheaper and less labor-intensive to repair. In fact, a manual transmission repair or replacement can often cost 50 percent less than fixing an automatic.

Industrial machinery has a lot of moving parts already. The more you can do to minimize repairs and downtime, such as using high-end Falk gear couplings and other Falk gearbox parts, the more your operation will save in the long run. Since choosing a manual transmission can make a big difference in terms of maintenance and repair cost, it may be worth it to resist making the shift to automatic transmission.

Posted under Falk Gearboxes on Friday, July 7th, 2017