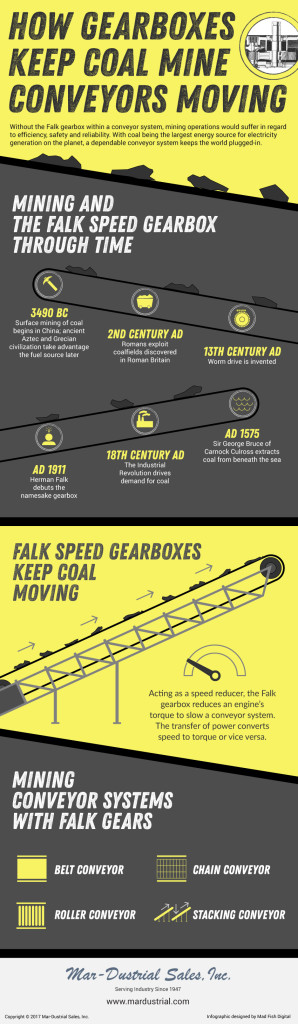

A combustible sedimentary rock, coal has been a vital source of energy since the 35th century BC. At the time of publication, it’s the largest source of energy for electricity generation worldwide. Thanks to the inventions that came with the Industrial Revolution in the 18th century, which paved the way for the use of Falk gears in conveyors, international coal trade expanded exponentially. Today, engineers continue to use gearboxes in conveyors to make transport mining materials more efficient.

Brief Mining History and the Role of the Falk Gearbox

Historians trace coal mining as far back as 3490 BC after archaeologists found evidence of surface mining of coal for household use in China, the world’s top coal producer. Ancient Greeks and Aztecs also used the resource for fuel. Major coalfields, however, weren’t exploited until the 2nd century AD when the Romans mined it in Roman Britain. After AD 410, records of coal mining stop until the late 12st century.

In 1575, Scotland’s Sir George Bruce of Carnock of Culross opened the first coal mine to extract coal from under the sea using an artificial loading island with a connection of shafts for drainage and ventilation. The rudimentary technology was the most advanced mining method of the late medieval period.

The small-scale mining techniques developed over the centuries proved inefficient and made it difficult to keep up with increasing coal demand as extraction moved from surface extraction to deep shaft mining during the Industrial Revolution. The invention of belt, chain and roller conveyors that use Falk gearboxes facilitated transport from underground to the surface, inspection and maintenance.

The Falk gearbox was in part responsible for the Bull Mountain Coal Field’s reopening. Gearboxes on the mine’s 4,000-foot conveyor supplied the plant’s primary fuel. Cutting machines in longwall mining pass along the face of coal, which falls to a conveyor for continuous removal so workers can prepare it for transport on nearby short-line railroads, which is vital to delivering up to 11 million tons of coal per year.

In mining operations, a Falk speed gearbox acts as a speed reducer that adjusts an engine’s torque to slow down a conveyor system. The worm drive within it was invented in the 13th century but remains a primary component after withstanding the test of time. The conveyor’s motor sends power to the speed reducer via the input shaft, converting the speed to torque or torque to speed. As a result, the gearbox transmits the load to the conveyor via the output shaft.

Mine Conveyor Types

Conveyor gearbox requirements depend on the mining application, as conveyors have their own gear reducer demands to endure harsh conditions found in mines.

- Belt conveyors: The most popular type of conveyor used in mines, belt, or feeder, conveyors use shaft-mounted gearboxes and can transport material over a slight incline.

- Chain conveyors: Chain conveyors typically use bevel-helical gear and parallel shaft units. They often use multiple specialty conveyor chains.

- Roller conveyors: Best for long loads, roller, or mainline, conveyors use gearboxes with compact designs and good torque characteristics.

- Stacking conveyor: A stacking conveyor system facilitates the piling of coal on the ground for storage. The system can create stacks of different shapes.

Engineers design gear drives to reliably meet the demands of a coal mine’s operating challenges, including reducing equipment stress and wear, improving performance, and extending a conveyor’s service life. Keeping coal moving is vital to producing the most tons of coal possible daily. With the ability to keep a conveyor moving at a precise speed, the Falk gear is the quiet workhorse that keeps systems efficient and safe.

Posted under Falk Gearboxes on Thursday, October 12th, 2017