Choosing the wrong gear coupling can be costly. Fortunately, Falk has designed a solution to save you money: Lifelign gear (G) couplings. With their low initial cost – along with the highest bore capacities and ratings available – Falk G couplings can save you as much as 35 percent over competitor brands.

Built to last longer, protect your equipment and save you money, Lifelign G couplings are ideal for a world of applications. They’re designed to AGMA standards and are interchangeable “half for half” with many other brands. With a wide variety of sizes and capacity ratings available, the durable G coupling gives users the broadest possible choice range – no matter the application or factory environment.

Falk G couplings are specially designed to remain your most economical solution. You don’t have to worry about quality or reliability. This means that time between maintenance is drastically reduced and service life increases. There are many more advantages like longer life, equipment protection, and interchangeability.

Longer Life

Longer Life

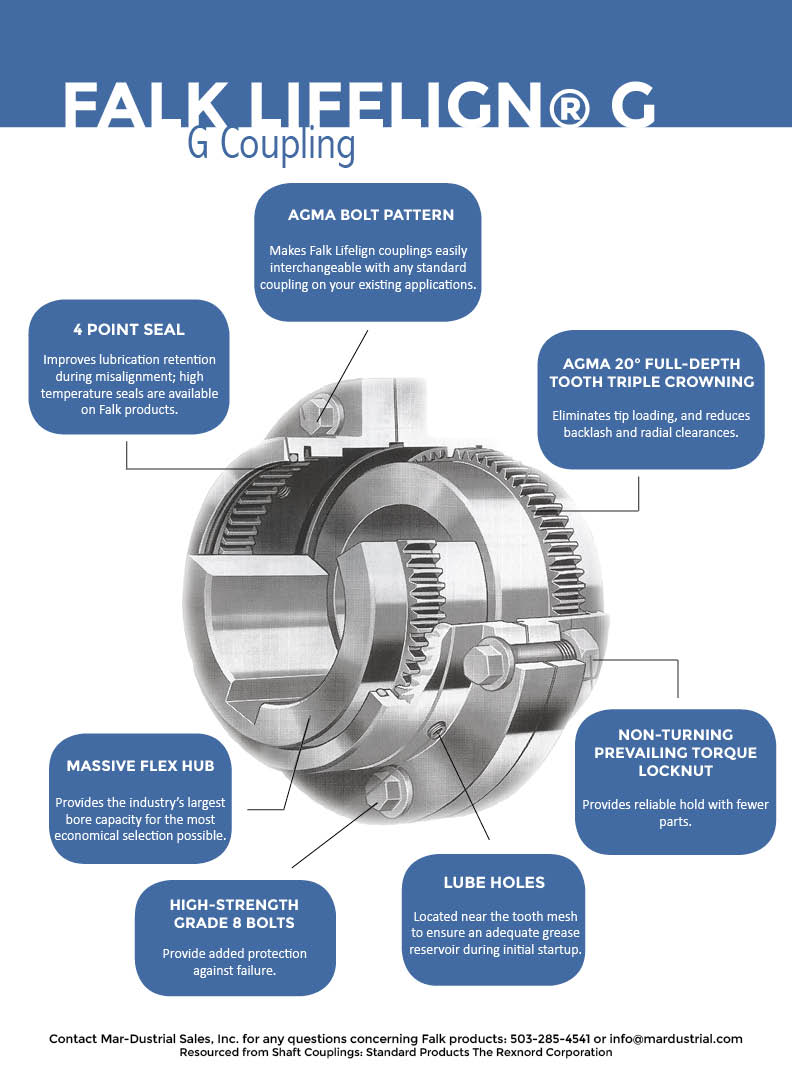

The Lifelign G coupling is built for a longer working life, with Falk’s superior Long Term Grease lubrication and a four-point seal to extend its lifecycle and reduce maintenance. It comes with a 3-year warranty when Falk Long Term Grease is used.

Equipment Protection

Equipment Protection

Triple-crowned teeth are designed with crowns on all working portions of the teeth, so they can slide freely to accommodate misalignment and movement. As a result, connected equipment is protected from damaging loads.

Interchangeability

Interchangeability

Because of their AGMA standard sizes, Lifelign G couplings are one-half for one-half interchangeable with other standard gear couplings, regardless of the difference in sleeve barrel, hub and bore dimensions.