The simplest, most cost-effective alternative to gear couplings.

The New Rexnord redefines total coupling value in the 22,001-8.5 million in-lb (2 501-932 Nm) torque range with Steelflex. It offers simpler initial installation than gear couplings. The unique “replace in place” design eliminates the need to move hubs or re-align shafts, reducing element change-out time. Plus, low initial coast and a guaranteed five-year, no-maintenance run time- with the use of long-lasting lubricant – assure the lowest lifetime operating coast in the torque range.

We invite you to learn more about the differences between grid couplings and gear couplings.

For more information, contact your Rexnord distributor. Or for the representative nearest you, see the Topics area.

Falk Grid Couplings Offer:

Longer Life

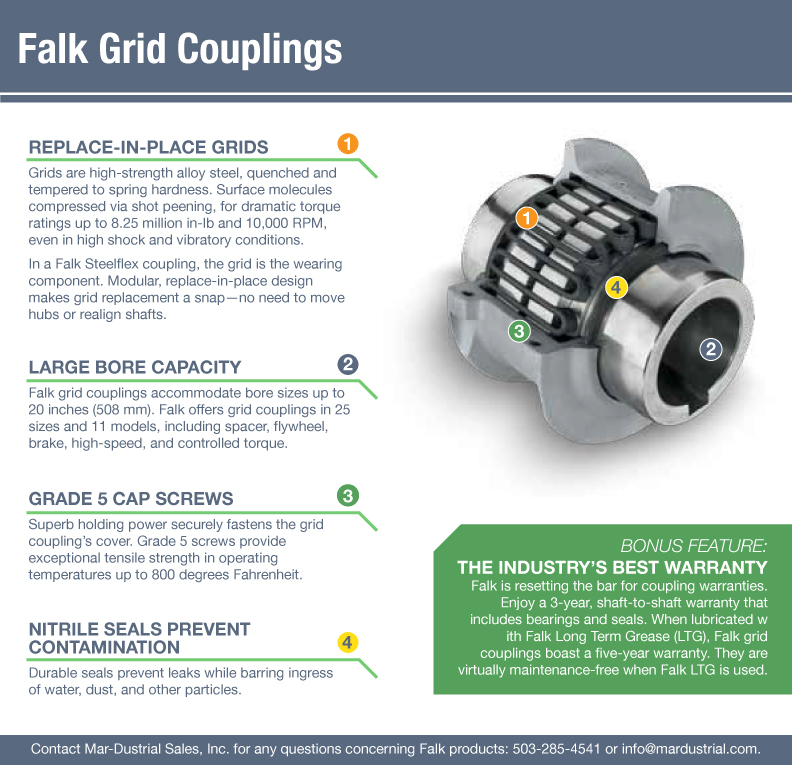

Tapered grids, made of high strength alloy steel, are quenched and tempered to spring hardness. The grid surface is then precision shot peened to compress the surface molecules. The effect is a dramatic increase in rating, providing reserve strength for longer life or allowing a smaller size coupling to be selected. This precision technology was originally used in the production of sophisticated aircraft components.

Extended Maintenance Periods

Now you can install the coupling and lubricate it with Falk Long Term Grease (LTG) and forget periodic, routine maintenance for five years. Falk LTG grease was developed specifically for couplings. It resists the separation of the oil and thickening agent that occurs in typical greases. The initial use of Falk LTG coupling grease will eliminate routine lubrication cycles while still providing the necessary lubrication to the tapered grid.

Quick, Easy Installation… Replace-In-Place Design

The grid is the wearing member of a Steelflex coupling and it is a fraction of the complete coupling cost. Tapered grids are accessible through the quickly removable cover. The replace-in-place design of the replacement grids allows them to be dropped in without the need to replace hubs or move and realign shafts and connected equipment as required with gear couplings and many elastomer designs. When coupling-connected equipment must be moved, the job takes longer and costs a lot more.

Equipment Protection Against Shaft Misalignment

The grid is free to rock, pivot and float within the hub teeth. Generous misalignment capacity is provided without producing detrimental bearing side loads created by other coupling types.

Equipment Protection Against Shock/Vibratory Loads

Torsional flexibility is the ability of Falk Steelflex couplings to torsionally deflect when subjected to normal shock or vibratory loads, providing flexible accommodation to changing load conditions. Consequently, the coupling is capable of tuning the drive system. It absorbs impact energy by spreading it over an increment of time. It damps vibration and reduces peak or shock loads by as much as 30%. It is a true shock absorber for rotary motion, relying on the predictable resilience of the steel grid for torsional flexibility.

Versatile Designs

Two cover designs are available in the popular sizes. Standard spacer, piloted, high speed, brakewheel or disc, and controlled torque designs are also available.

Worldwide Availability

Steelflex couplings and component parts, in popular sizes and types, are available from Falk distribution center stocks, or from our world, wide distribution network with the largest stock of rough bore, finish straight bore and Taper-lock bushed hubs of any shaft coupling on the market.

The function of a coupling is to connect two shafts, plus to protect expensive driving and driven equipment from misalignment, shock loads, vibration and thrust loads.